Smart Solutions For Your Business

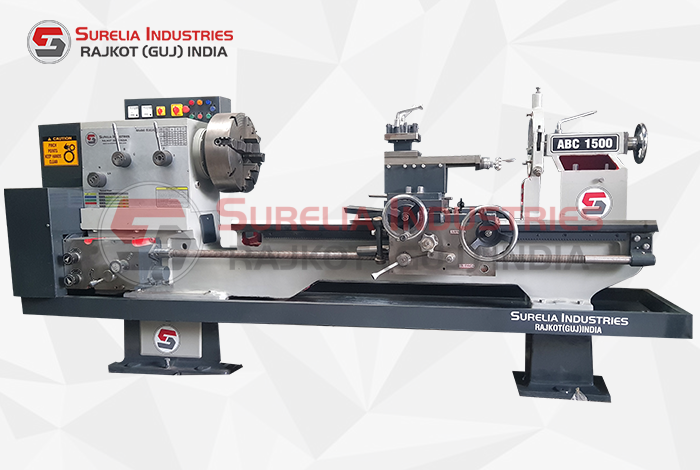

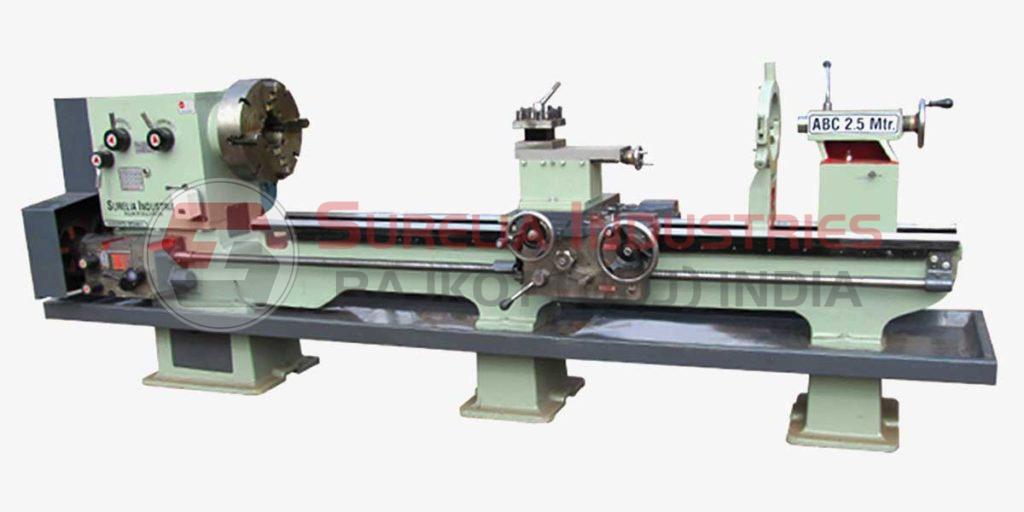

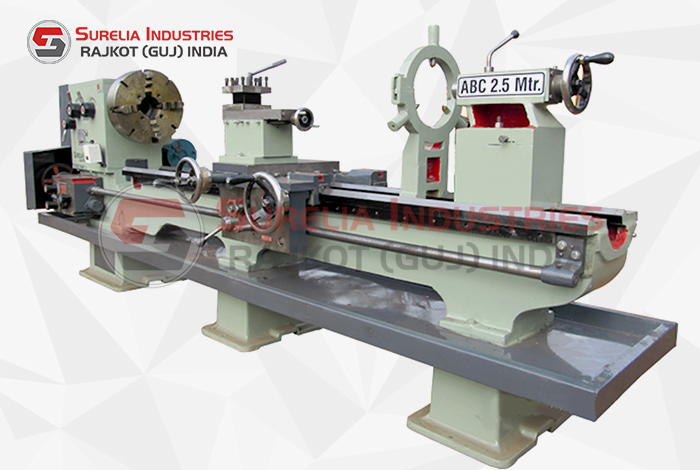

Surelia Industries is one of the foremost Heavy Duty Lathe machine manufacturers supplying machines to various parts of the world to work with heavy loads. We design these machines using powerful features with high capacities to turn large metal workpieces.

Our machines are equipped with special features such as ground headstock spindles rigidly structured induction hardened and precisely ground Lathe beds that provide a solid base & simultaneously facilitating the seamless parallel movement of carriage & tailstock in alignment with the axis of the spindle.

All Details Of Our Product

- Follow Rest

- Change gear – B.S.W.-13

- Dead centers- 2 Nos.

- Tool Post Key

- Steady Rest

- Motor Pulley

- Change gear- M.M.-3

- Chuck Plate

- Center Adapter

- Face Plate

- Threads – 4 T.P.I

- Head Stock Belt – Buss Type

- Floor Space – 1250 x 2500 mm

- Range of spindle speeds – 30 to 500 R.P.M.

- Swing over slide – 280 mm

- Tail Stock Spindle Diameter – 60 mm

- Motor Power – 2 H. P

- Between Centre – 5′-6″, – 500mm to 12′, – 2500mm

- Spindle speeds – 8 R.P.M.

- Compound slide swivelling degree – 45-0-45

- Tail Stock Spindle Travel – 200 mm

- Metric Threads – 1 to 7 mm

- Net Weight of Machine – 1300 kg

- Swing over bed – 450 mm

- Tail Stock Taper Bore in Spindle – M.T. – 4

- Carriage size – 450 mm x 500 mm

- Head Stock Taper Bore in Spindle – M.T. – 6

- Height – 1300 mm

- Width of bed – 325 mm

- Cross slide travel – 280 mm

- Swing in gap – 760 mm

- Cross slide size – 200 mm x 500 mm

- Layout – Horizontal

- Length of bed – 2130 mm

- Admit Between Centre – 1000 mm

- Hole through the spindle – 50 mm

- Inches Threads – 4 to 28 T.P.I.

- Spindle nose – 6 T.P.I.

- Top slide travel – 150 mm

- Diameter – 38 mm

We use alloy steel to provide strength & sturdiness to the machine for lasting durability.We are manufacturing this heavy duty model lathe machine with V belt driven and all geared driven. We use an oil pump that helps to lubricate the rotating spindles & bearings to provide more power to the machines by neutralizing the inner frictions & tensions within the Lathe mechanism and also helps in the process of cooling overheated parts. In addition, we have used bayonet type spindle nose fittings to ensure a valuable fastening mechanism, to improve safety & to allow easy replacement of the parts. We offer a wide range of Heavy Duty Lathe machines with different specifications, accessories, sizes & features.