Smart Solutions For Your Business

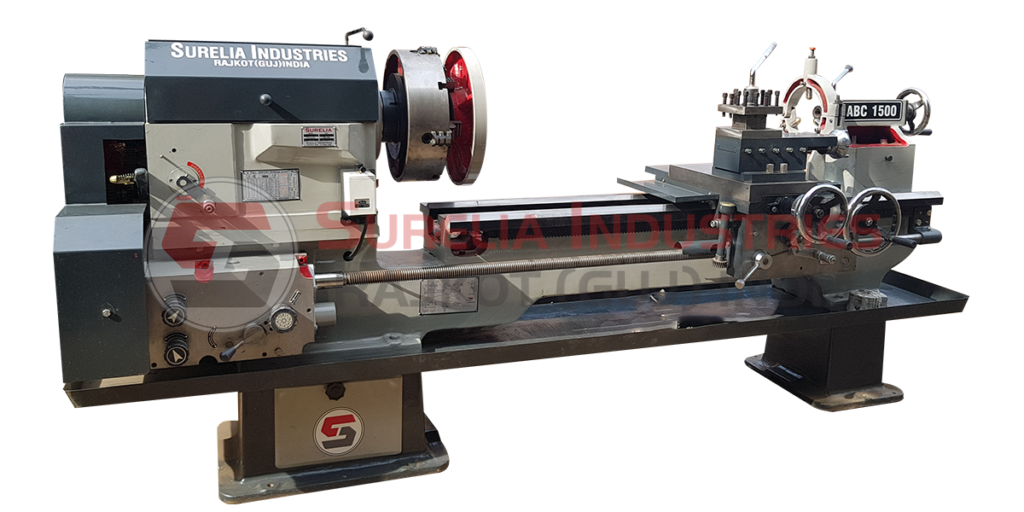

We supply Cone Pulley Lathe machines that are known for multi-functioning including Turning, Parting, Thread Cutting, Tapper Turning, knurling, cutting & drilling.

Our skilled engineers make these machines as per International standards to achieve high efficiency & performance. We supply the Cone pulley Lathe machines in various technical specifications as per the various requirements of our customers.

All Details Of Our Product

- Follow Rest

- Chuck Plate

- 2 Nos. Dead center

- Tool post spanner

- Steady Rest

- Face Plate

- Spindle sleeve

- Change gear set

- Switch stand

- Rear Tool Post

- Norton gear box

- Electrical Coolant Pump with Fittings

- Flame Hardened Bedways

- Electric Motor

- Reversible Switch

- Extra Spindle Hollow

- True Chuck

- Extra Center Height

- Tapper Turning Attachment

- V-Belt

- Dog Chuck

- Machine Lamp

- Bed Length Range-2.5 ft to 50 ft

- Bed Width – 230 mm to 1200 mm

- Spindle Bore – 30 mm to 400 mm

- Admit between Center – 12inch (300 mm) to 500 inch (13000 mm)

- Height of Center – 6.5 inch to 40 inch (1000 mm)

- Motor Speed – 1440/960/750 R.P.M

- Motor Power – 1 H.P to 40 H.P./

- Voltage – 440 V

- No of Speeds – 8

- Metric Threads and Range – (1 to 6 mm pitch): 13 Inch/(2 to 24 TPI): 19

- Phase – 3 Phase

- Electric/Electronic industries

- Manufacturing industries

- Engineering industries

- Mechanical industries

- Paper Industries

- Cement Plant

- Auto Industries

- Tool Room Purpose

- All rotating parts are balanced.

- Headstock spindle is made of alloy steel & precision ground.

- Induction hardened and precisely grounded bed ways.